【 Japanese Page >> 】

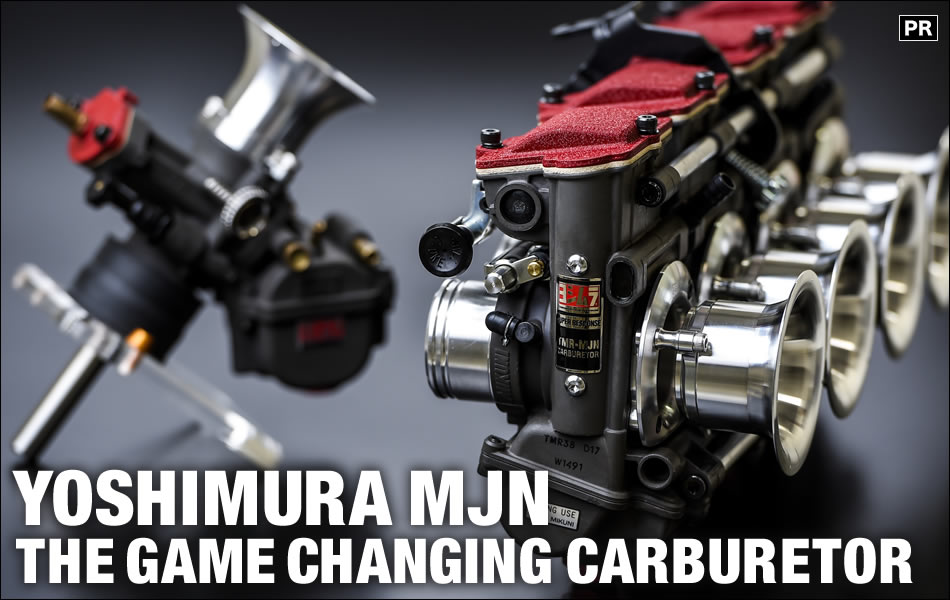

In 1971 Hideo “Pop” Yoshimura invented the 4-into-1 exhaust system which forever changed the look of 4-stroke motorcycles. The innovation immediately made Yoshimura world-famous as a master of exhaust systems, but keep in mind that his company has long been working on each and every aspect of engines since its foundation in 1954. One of its areas of expertise is the carburetor upgrade, which has been proven successful over the years as well as with a device invented in 1992 by the current company president Fujio Yoshimura. The invention is called the Multiple Jet Nozzle (MJN) and it was ingenious.

MJN: How different?

Conventional carburetor draws fuel through the gap between tapered jet needle and cylindrical needle jet. Jet needle slides up and down through needle jet to adjust the amount of fuel entering from the main jet in the float chamber in response to throttle control. Pilot jet (slow jet) in the float chamber meters fuel for low rpm range including idle speed, through its extremely small hole.

Conventional carburetor draws fuel through the gap between tapered jet needle and cylindrical needle jet. Jet needle slides up and down through needle jet to adjust the amount of fuel entering from the main jet in the float chamber in response to throttle control. Pilot jet (slow jet) in the float chamber meters fuel for low rpm range including idle speed, through its extremely small hole.

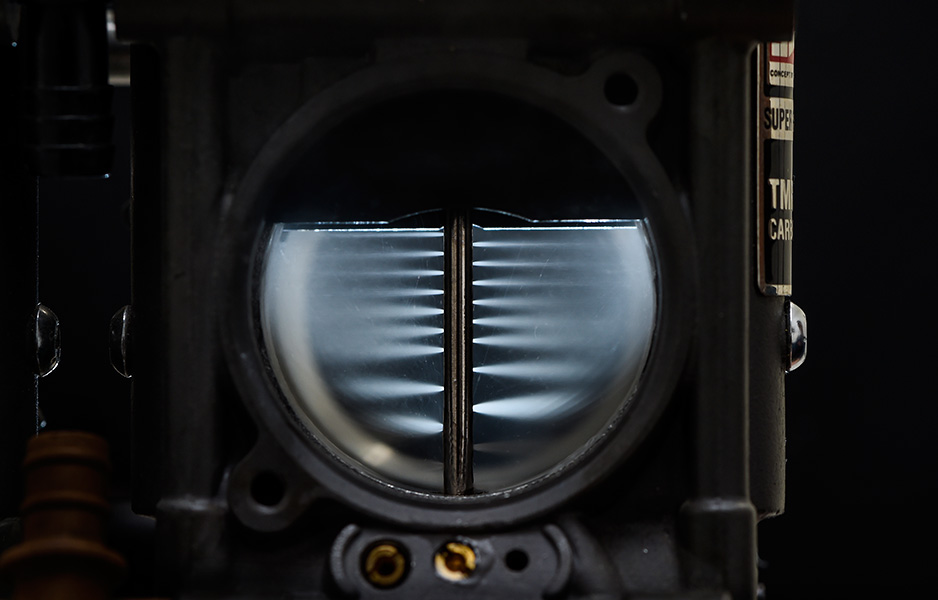

The gap between jet needle and needle jet is located at the bottom of carb throat where the vacuum pressure / air velocity is low. Although the jet needle can adjust the amount of fuel with its tapered section, it cannot deliver fuel to the center of carb throat (the middle of the Venturi) where the vacuum pressure / air velocity is highest. Atomization in this manner is also far from optimal since fuel-air mixture tends to flow close to the bottom of the carb throat when the throttle valve opens during the transition from part throttle to full throttle.

MJN is a unique device made out of a straight hollowed tube which is made in-house, that replaces conventional jet needle. Through the multiple holes on its sides where the most vacuums are created and sprayed, MJN ejects fuel throughout the carb throat and achieves improved atomization and higher charging efficiency by taking advantage of the high vacuum pressure.

P.S. The conventional jet needle type carb does draw the fuel through its gap between needle jet and Jet needle to main bore when even throttle valves are fully closed vs. with MJN nozzle fuel drawing is very minimum. Let’s image, you are entering corner with throttle fully closed, with needle jet type carb which draws fuel into combustion chamber to the point where spark plugs could get almost flooded vs. MJN such effect is very minimum due to again using straight hollowed tubes. This effect would make your transient accelerating throttle work much smoother.

Fujio Yoshimura, the inventor of MJN

Where the inspiration for the MJN carburetor came from? Fujio Yoshimura (president of Yoshimura Japan) says it came to him in a flash during the late 1980's, while his team was fiercely struggling on the track against rivals.

Where the inspiration for the MJN carburetor came from? Fujio Yoshimura (president of Yoshimura Japan) says it came to him in a flash during the late 1980's, while his team was fiercely struggling on the track against rivals.

“MJN was launched in 1992, but its development dates back to somewhere around 1988, when we were racing the oil-cooled machines. The race carbs on the oil-cooled GSX-R750's were becoming bigger and bigger, from the original 36 mm to 40 mm, to get more power. Sure, it worked and we got more power out of the engine, but its transient response, throttle response and fuel consumption got worse. Big carbs have downsides ---- that's just what they are. Anyone who have experience with big carbs would know what I'm talking about. It just doesn't quite respond to the initial twist of the throttle as crisp and snappy as the stock carb. So I thought about a solution, and suddenly came up with this idea of placing fuel jets at the center of the carb throat.”

It was the idea of using a tube with rows of holes ---- later to be known as a Multiple Jet Nozzle (MJN) ---- instead of a jet needle. This novel method allows the fuel to be ejected from the most optimal position in the carb throat. Before the MJN, there were already several carburetors in the market that had been designed to pull the fuel further up the needle (like the Lectron with a grooved needle), but while they deliver good full-throttle performance, they have drawbacks such as poor transient response and the difficulty of adjustment due to the eccentric design of their fuel control mechanisms.

“The very first prototype we tried only had 4 holes, one for every quarter throttle, on just one side. I think all of the holes had the same diameter, but it didn't matter. I just wanted to try. The prototype tube was handmade on a lathe. As soon as we fired up the engine, and even with the improvised prototype, we could tell the difference. The engine sounded quite different as well. I knew I hit the jackpot. We then asked Doug Polen (Dual Champion in 1989 All Japan TT-F1 & TT-F3, who was in the Yoshimura team then) to test it. But that's just the beginning.”

Ultra-precision machining required

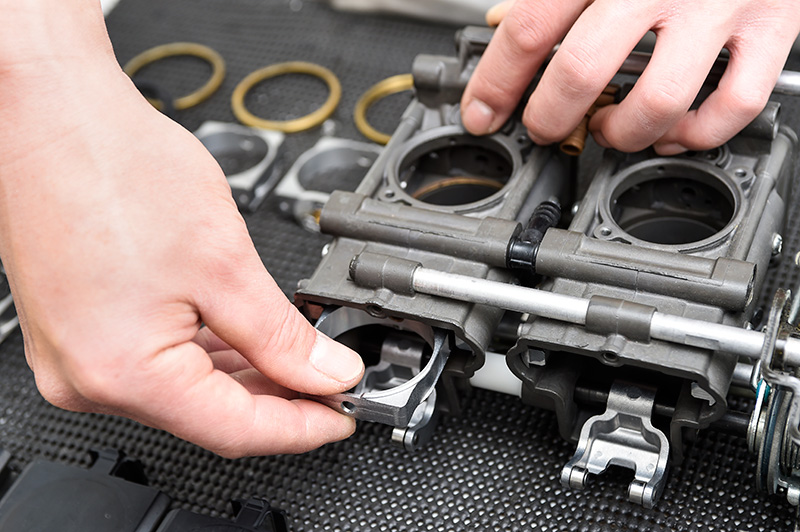

Drilling holes into a narrow tube about as thick as a jet needle is not an easy task, considering that jet needles usually need to be machined with a precision of 1/100 mm. Not many in the world can provide this sort of ultra-precision machining.

“The whole trial and error process took about 2 years. We've tried all kinds of machining including laser drilling ---- and ultimately found out that the best way to make these microscopic holes is with mechanical micro-drill bits since they provide the highest precision and cleanest cut. We've also tried various combinations of holes in different positions, sizes and numbers ---- followed by determining the clearance between the MJN and its guide, verification of their material, surface treating, wear properties ---- and the list goes on. Well, it took us quite a lot of time to develop, and that's because we were trying to build a durable product that would withstand not only the hours of racing abuse but also the rigors of street use.”

The micro-drill bits are fixed to the high precision machine tools in the factory. Prior to the launch of MJN, Yoshimura Japan has invested in new tools and equipment including a CNC (computer numerical control) lathe that was specially designed for producing MJN tubes by boring into brass billets.

Simple conversion

One of the merits of the MJN is the ease of conversion. You can transform your conventional carburetor into a MJN conversion, just by replacing the jet needle with the MJN and the needle jet with the MJN guide, without altering its basic construction. The simplicity saves cost and thus provides reasonable price.

“Also it wouldn't have been possible without the Mikuni's the high-performance TMR carb. Its precision and performance are beyond comparison to the obsolete carburetors. Installing TMR's on a classic like a CB750 Four or a Z1 will make it almost like a modern bike ---- it will be running a whole lot smoother, much easier to handle and so much more powerful. And with a MJN, it will be even smoother. That's just not possible with vintage carbs.”

Instant upgrade in power and efficiency

“With a MJN, you can use a smaller main jet than normal because of the better atomization ---- which leads to better fuel efficiency and mileage. The transient response will be better also. It will definitely run smoother and will provide better throttle response at upper-throttle range. There's really no negatives to it.”

As you ride a bike (any bike) equipped with MJN, you'll notice the difference in smoothness. MJN also makes the carburetor adjustment a breeze. If you are working on a 4-cylinder bike, you basically need 2 MJN's for Mikuni TMR (one for large body and another for small body) in addition to some jets and screws. Every MJN kit is custom engineered for a specific motorcycle application.

“We had found out through our experiments that one MJN can cover a wide range of carburetor sizes and engine types. Probably because it delivers an optimal amount of fuel according to the vacuum pressure created by the engine. Adjusting a conventional carb on the other hand, requires considerable jetting skill ---- you need to select the proper taper type, straight section diameter and so on. There are so many jet needle profiles to choose from, and it takes time to find the right jet needle and needle setting, especially during races, in which you have to re-adjust the jetting at your pit area. So, the simplicity of the setting is a great advantage in winning races. It's an advantage for street riders, too ---- such simplicity of jetting and screw adjustments would allow them to enjoy setting up the carburetor.”

MJN brings a unique alternative to the era of EFI (Electronic Fuel Injection); pushing even further the performance limits of yesterday's carbureted motorcycles such as oil-cooled Gixxers. It also brings us opportunities to re-discover the appeal of carburetors.

Making carburetor environmentally friendly

Better fuel efficiency means less emissions. MJN reduces the risk for environmental pollution by reducing CO (carbon monoxide) and HC (hydrocarbons) emissions.

“It was inevitable that the industry had to shift its attention towards the environment, and the EFI is also easier to produce. But it seems like a waste of knowledge and experience to dump the technology that still holds some potential for future development. Because of its low fuel consumption, MJN carburetors has been popular among those who participate in fuel efficiency competitions. Its high fuel efficiency also gives less pollution, so you can enjoy riding an environmentally-friendly, better-performing bike by simply converting your carbureted bike with a MJN.”

Two are always better than one

It has been long known that long stacks are for low rpm, and short stacks are for high rpm. There was an attempt previously to combine the benefits of both types, and it was called ”variable length velocity stacks”. It became somewhat popular during the 1990's among the racing teams and Team Yoshimura was no exception but, due to its slow response, mechanical complexity and high cost, it eventually faded away from the motorcycle racing scene. Then came street bikes equipped with different-length velocity stacks; some 4-cylinder bikes had 2 short stacks on the outer cylinders and 2 long stacks on the inner cylinders. And in 2005, Yoshimura Japan began testing their Dual Stack Air Funnels on the tracks.

“We've tried all kinds of combinations, of lengths and clearances, while keeping the suction resistance to a minimum. And this is the best configuration we found after the extensive experiments. As is the case with MJN, it all began with an inspiration, and we follow it to where it leads, through this trial-and-error learning process. You might later come up with a theory for it, like the one for our 4-into-1 exhaust system, but first, you need to actually try it out to fully understand how it works.”

The invention was named Dual Stack Air Funnels. It would be even more effective when it is combined with the TMR-MJN.

“Aftermarket performance parts such as MJN and Dual Stack Air Funnels will definitely always have an appeal to enthusiasts.”

“Carburetors still have a future despite the emergence of EFI. EFI's are just too complex for the average motorcycle owner to handle. That's one of the reasons Yoshimura Japan developed the YD-MJN carb. It is designed for the small engines that are popular in Asia, and Asian motorcyclists in general prefer simple mechanisms. From now on, the motorcycle racing and tuning industry will be much more important in Asia. Motorcycle enthusiast all over the world will continue to enjoy riding and working on bikes. The performance tuning and customizing are all about feeling the differences ---- and these differences consequently bring even more joy to their lives.”

MJN's atomizing performance exceeds expectations.

MJN's atomizing performance (micro-misting of fuel) is beyond expectations. As the throttle opens, atomization becomes more intense, producing a white cloud of fuel across the carburetor throat. The beauty of Yoshimura MJN carb is that it takes advantage of the strong vacuum pressure developed at the center of the throat, and its superiority over the conventional carb with a single main jet is obvious. It's a perfect example of a great concept and design.

The perfect combination of performance and appearance.

Clad in black and red color scheme, MJN series carburetor stands out in both performance and appearance. The joy of owning this sophisticated mechanical gem becomes even greater when you witness its incredible atomizing performance with your own eyes. The unmistakable “Yoshimura Red” accent color adds a sense of class and mysteriousness to the device. It definitely will look awesome especially on a naked bike. Note: Yoshimura MJN series carburetor is a registered Utility Model under Japanese patent legislation.

Maintenance and customization available for TMR & TMR-MJN.

Every carburetor needs a regular maintenance, and some of its parts may need to be replaced after being used for a period of time. Yoshimura Japan provides support services including overhaul and customization (modification needed for carb swapping, converting to MJN and so forth) of the Mikuni TMR & TMR-MJN carbs for you to get the most out of them for many years to come.

Note: Support services including overhaul and customization are available only in Japan.

TMR-MJN

Mikuni TMR with built in Multiple Jet Nozzle. Available in single, twin and quad carb setups of both large body (with sizes ranging from ø36 to ø41 mm) and small body (from ø28 mm to ø35 mm); for a wide variety of applications including classics (such as Honda CB750 Four and Kawasaki Z1), Katana, oil-cooled GSX-R, Ninja 250R and more.

FCR-MJN

MJN conversion of the Keihin FCR, another up-to-date race-proven carburetor, also comes in black body with red cap. Available for a wide variety of bikes including ZRX1100 & 1200, Ninja GPZ900R, Z1, SR400/500 and NSF100.

YD-MJN

High-performance downdraft carburetor designed and built by Yoshimura Japan for horizontal singles. Available in ø24 mm and ø28 mm, together with special manifold and insulator, and will fit the stock Monkey frame and tank.

TM-MJN

MJN conversion of the already very responsive Mikuni TM. Available for various mini bikes such as Monkey (special manifold kit also available), Ape 50 & 100, XR 50 & 100 Motard and NSF100.

CR-mini MJN

MJN conversion of the Keihin CR-mini. The CR-mini ø22 mm + MJN setup is still very competitive in mini bike racing. Available in black and silver; for the vertical XR100 series engine with stock head / Yoshimura head.

MJN Inner Kit

Retrofit kit for converting standard carburetor to a MJN version. Applications include Keihin CR Special ø29 mm & ø33 mm (for Kawasaki Z1 & Z2) and CR-mini single. Yoshimura Japan also offers a special service for converting your TMR into a TMR-MJN.

Dual Stack Air Funnel System

Dual Stack Air Funnels are available for a variety of applications. Shown in the pic are the short Dual Stack Air Funnels designed for TM-MJN ø22 mm carb on mini bikes, and are available in these 3 colors.

The well-respected Japanese racing constructor / aftermarket parts manufacturer & supplier, started its business in 1954. The company has been racing and tuning Suzuki motorcycles since the late 1970's following the years of dedication to Honda and Kawasaki. Their product development, however, is targeting diverse applications ranging from 4-stroke minis to supersports of various brands.

6748 Nakatsu, Aikawa-Machi, Aiko-Gun, Kanagawa-Pref. 243-0303 Japan

Official Website: www.yoshimura-jp.com/en/